REFRIGERATED CARGO

Transporting Perishables

Fruit and vegetables are living organisms, they respire even after harvesting. Respiration is part of the natural ripening process. During respiration, they generate heat and give off gases and moisture that will speed up deterioration as well. Controlling the following factors can reduce deterioration of perishables:

Temperature Maintenance

| Cooling the temperature is the most powerful and effective way to minimize deterioration. The faster the proper temperature is reached, the longer the expected life of the product. Cooling of fresh produce should begin as quickly as possible after harvest. Reefer containers should not be used to reduce the temperature of the cargo. Instead, they are designed to maintain rather than to lower the temperature of the cargo. Therefore, precooling all perishable products immediately after harvest and before shipment or storage is essential. |

|  |  |

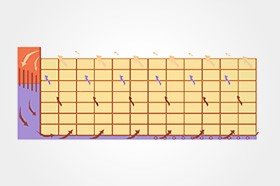

| Humidity | Ethylene | Air Circulation |

| Relative humidity directly affects the quality of almost all products. If humidity levels are too low, fruits, vegetables and related products may wilt or shrivel. If relative humidity is too high, mold may develop to deteriorate the cargo. | Another way to minimize deterioration is to remove the ethylene gas. Ethylene, a self-generating fruit- ripening regulator, is necessary for the ripening of fruits and vegetables. However, it can also cause damage to various fruits, vegetables if it is not controlled in minimal level. We can minimize and control its accumulation by adequate ventilation. | Poor circulation can affect the commodity’s temperature, relative humidity and ethylene accumulation. If the air cannot circulate properly in the cold room or container, shelf life of the product will be definitely affected |

| ||||||||||||

|

Proper pre-cooling of the products will have a positive effect on their shelf life and improve the cargo outturn. The products should always be pre-cooled to the required carriage temperature prior to being stuffed into the container. Furthermore, reefer containers are built to maintain the temperature of the products rather than to decrease the temperature. When the products are loaded at temperature above the carriage temperature, the strain on the reefer unit will be considerable and can eventually result in the breakdown of the machinery. Before loading pre-cooled products, the container should also be pre-cooled by operating the unit with the doors closed for about 30 minutes, or until the set temperature is reached. Once pre-cooled the unit should be turned off and product loaded immediately for best results. If the hot humid air enters the refrigeration unit, moisture condensed on the cold cooling coils and turns to ice. Cooled air is not confined to the container and escapes out the rear door as the cycling continues. The unit should remain off during loading and unloading to avoid the buildup of excess ice on the cooling coils. Once ice formed, the machinery will go into a short defrost mode. As a result, less capacity will be available for cooling the cargo. The check lists should always be followed before and during loading the shipment of perishable products: Prior Loading Checklists

Pre-cooling of Product

Pre-cooling of the Container

Check Lists

Packing requirements Ventilation Packaging Loading Patterns

Frozen Products

Packing requirements

The packaging material must be able to support a stacking height of up to 2.4 meters(7’10).Ventilation

When frozen products are transported, the fresh air ventilators must always be closed.Stowage

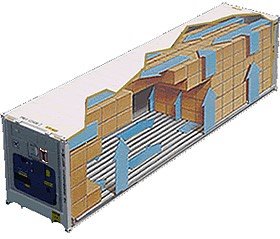

The stowage of frozen products is very simple. The only requirement is a solid block stowage, leaving no space between the packages and no space between the cargo. Most importantly, the cargo should be stowed below the red load line as this allows the refrigerated air to circulate evenly around the cargo, thereby maintaining the frozen products at the required temperature.Chilled Products

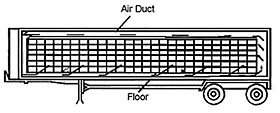

The packaging material must be able to support a stacking height of up to 2.4 meters (7’10). The material should be able to withstand humidity without collapsing and should allow the passage of vertical air flow through the cartons, in order to maintain the required. As the air flow comes from the bottom of the container, circulation will the optimum air be achieved if each carton has symmetrical hole at both top and bottom.

The ventilation of chilled products is necessary in order to remove the heat, carbon dioxide and gases produced by the cargo. Heat is removed by continuously circulating the internal air, whereas carbon dioxide and gases are removed by replacing the internal air supply with cooled fresh air.Stowage

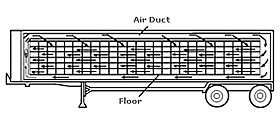

The live chilled products respires to produce heat, water vapor, carbon dioxide and gases, which may deteriorate the product and should therefore be removed. The stuffing should allow the refrigerated air to circulate through the packaging material and throughout the entire load.

There are two standard loading patterns for chilled products:Palletized cargo stowage

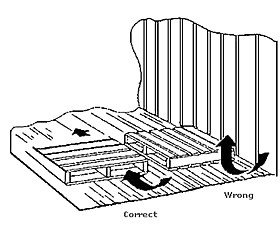

The products should be stacked in solid block way, without any space between the cargo and the walls of the container. If the cargo cannot cover the entire floor area, heavy cardboard must be placed in the empty space. This will prevent the air from “ short - cycling”, which means finding the easiest way, resulting in the insufficient cooling of the cargo. Cargo may not be stowed above the red load line. This is in order toBlock stowage

The guidelines of block stowage should be followed, and the following points are recommended: The cartons must be stacked squarely on top of each other, in order to ensure that the weight is evenly distributed on the four corners of the cartons. The ventilation holes, located at the top and bottom of the cartons, must be aligned in order to allow the air to pass through the entire load. It is not recommended to use shrink-wrapped pallets, slip sheets, foam trays, plastic bags or similar materials which may obstruct and block the air circulation through the cargo.

Products which are temperature - compatible may not possess compatible inherent characteristics. For example, products such as green leafy vegetables, mushrooms, rhubarb, sweet corn and butter are highly susceptible to absorption of odors. They should not be mixed with products possessing strong offensive odors. Similarly, products with vastly different temperature requirements should not be mixed. Averaging temperature of these types of products may result in accelerated ripening or decay of some products and chilling injury and eventual accelerated decay of the others. Products shipped together should be compatible not only according to temperature, but also according to relative humidity, ethylene sensitivity and odor characteristics. Compatibility for Commodities

Compatibility of Fresh Products

in the same group should be or are normally shipped together, it does mean they may be shipped together if circumstances require it. These recommended settings should be used with discretion, depending upon the actual load. The accompanying table (below) lists compatibility groups. While compatibility does not imply crops

Fig5

Fig5